Thick sheet vacuum-formed pallets are a versatile packaging solution known for their durability and flexibility. In this article, we will explore the process and features of these pallets, specifically focusing on HDPE nine-leg pallets, dividers, covers, and the material applications of PP and HDPE. Additionally, we will introduce the concept of detachable collapsible bulk containers made using vacuum-forming technology.

Process and Features of Thick Sheet Vacuum-Formed Pallets:

Thick sheet vacuum-formed pallets are manufactured using a specialized vacuum-forming process. High-density polyethylene (HDPE) is a commonly used material due to its strength, impact resistance, and ability to withstand heavy loads. HDPE nine-leg pallets offer enhanced stability and weight distribution, making them ideal for industrial applications.

Dividers and covers are integral components of thick sheet vacuum-formed pallets. Dividers help organize and separate products during transportation, ensuring proper placement and preventing damage. Covers provide protection from dust, moisture, and other elements, ensuring the integrity of the packaged goods.

Material Applications: PP and HDPE:

Polypropylene (PP) and HDPE are widely used materials in the vacuum-forming industry. PP offers excellent chemical resistance, high rigidity, and good impact strength, making it suitable for various packaging applications. HDPE, as mentioned earlier, is known for its robustness and load-bearing capacity, making it an ideal choice for heavy-duty pallets.

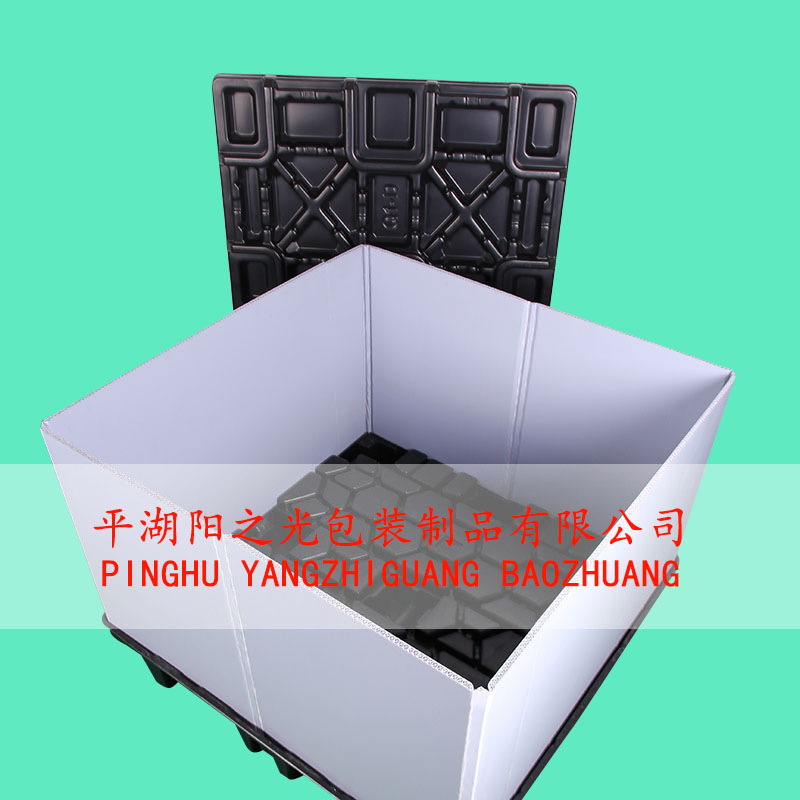

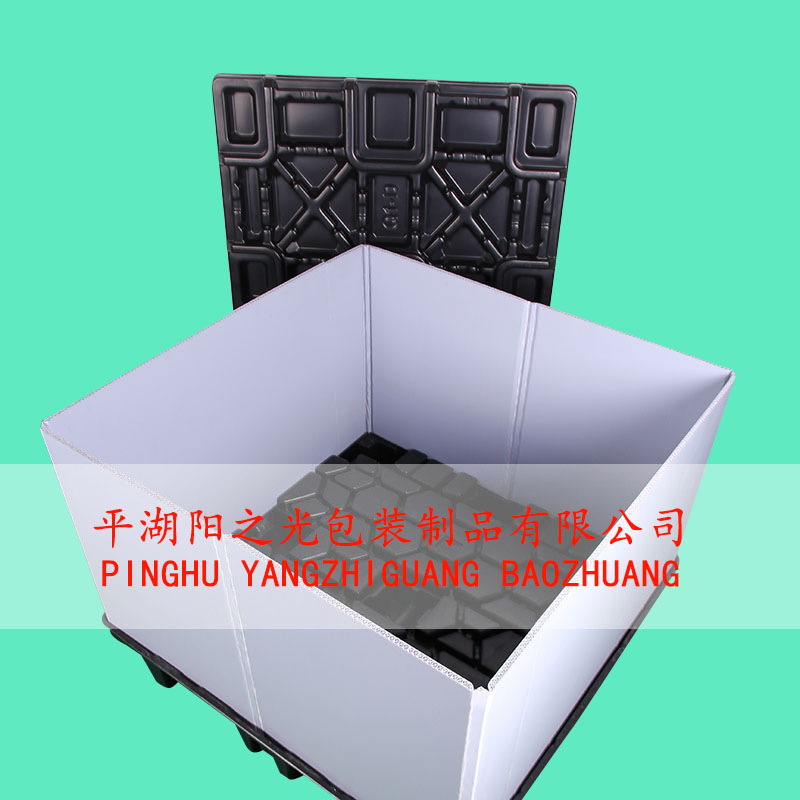

Introducing Detachable Collapsible Bulk Containers(Plastic Pallet Box):

In addition to pallets, vacuum-forming technology allows for the creation of detachable collapsible bulk containers. These containers provide a cost-effective and space-saving solution for storage and transportation. With their ability to be easily assembled and disassembled, they offer flexibility and convenience in managing bulk goods.

Conclusion:

Thick sheet vacuum-formed pallets, including HDPE nine-leg pallets, dividers, covers, and other components, offer a reliable and efficient packaging solution. With material applications of PP and HDPE, these pallets provide durability and stability for various industrial needs. Additionally, the vacuum-forming process enables the production of detachable collapsible bulk containers, further enhancing efficiency and cost-effectiveness in logistics and storage operations.