Translation:

Thick sheet vacuum forming and thin sheet vacuum forming may differ by just one word, but they have significant differences. Let's explore the specific distinctions between the two:

1. Thick Sheet Vacuum Forming:

Specialized thick sheet vacuum forming typically involves a thickness range of 0.5 to 15.0mm. It primarily utilizes materials such as PVC, PET (including APET and PETG), PS (HIPS), ABS, PP, PC, PE, PMMA, and other materials combined with injection molding techniques. The main products include advertising lightboxes, refrigerator liners, pet cage bases, product display racks, rear shells for projection TVs, and various mechanical panels. Thick sheet vacuum forming can serve as an alternative to injection molded products, offering advantages such as lower mold costs (only 1/20 of injection molds), shorter production cycles, and faster mold development time (usually only 3-5 days).

2. Thin Sheet Vacuum Forming:

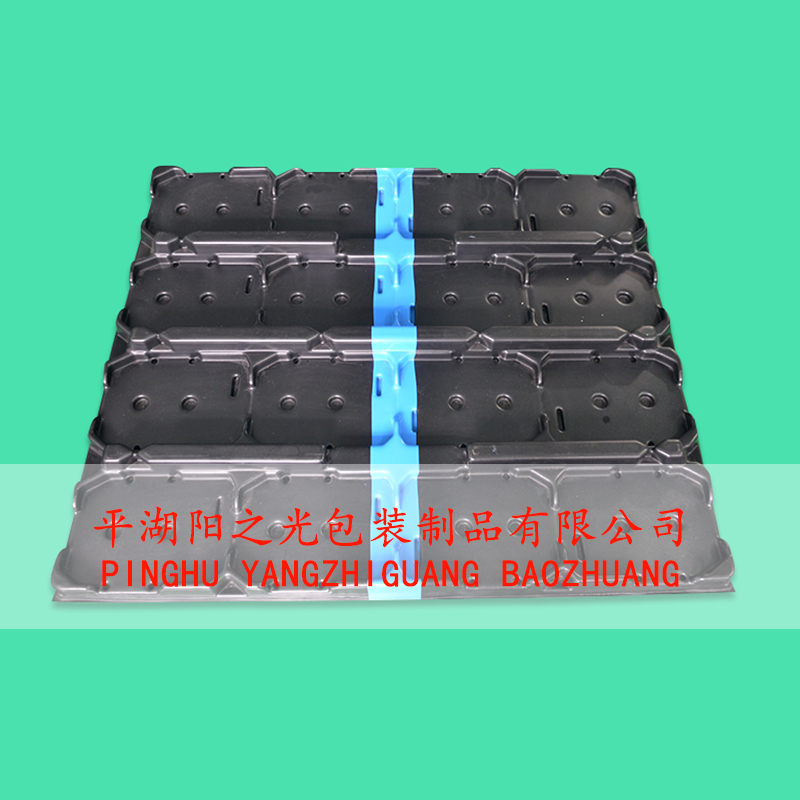

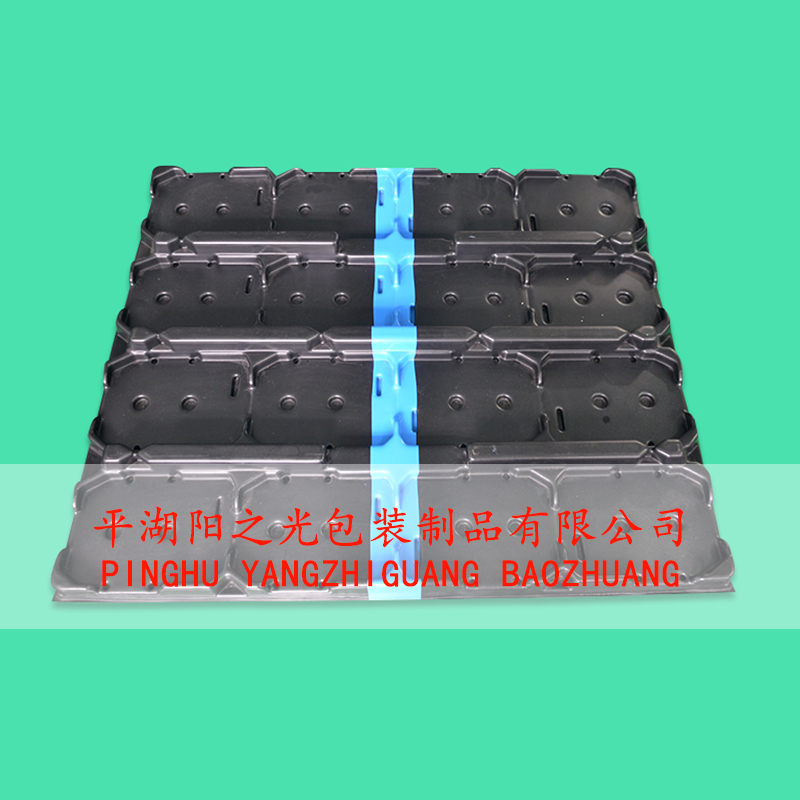

Ordinary thin sheet vacuum forming typically involves a thickness range of 0.14 to 2.0mm. It mainly utilizes materials such as PVC, PS (HIPS), PP, PET (including APET and PETG), PE, BOPS, and recyclable paper trays. These materials are used for folding, edge folding, tri-folding, foldable boxes, cylindrical shapes, high-frequency welding, and clamshell packaging in non-thermal-formed vacuum forming products. Thin sheet vacuum forming is widely applied in industries such as pharmaceuticals, electronics, food, computers, toys, cosmetics, daily necessities, and mechanical hardware.

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686