For more custom product options, Contact us!

|

|

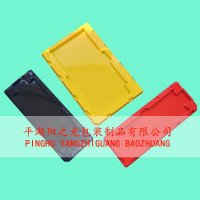

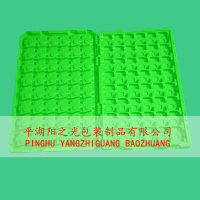

Vacuum forming inner tray for hardware tools, Plastic packaging tray, Customized packaging

Collect

The hardware vacuum form supportive insert tray is formed by heating a plastic sheet, vacuum forming on the surface of the mold, cooling molding. Then, through a plate cutter, die cutter, stamping, or a variety of trimming machines, the excess blanking is removed to form the desired final shape. This process has the advantages of low mold cost, short production period and short mold development time. Greatly reduce the product cost and development cycle. According to customer requirements to produce a variety of specifications and sizes of products, enough to ensure your product assembly accuracy.

Why choose us?

1.More than 20 years of experience in the plastic industry. we are able to design, develop and produce all elements in-house; from design to forming and CNC cutting. We are also able to carry out complex assembly of the final product for you. 2.We are the source factory which provides product OEM&ODM customization service according to customers' needs.

3.Advanced production equipment, fast supply. The introduction of international advanced automatic production equipment 15 sets, more than 100 employees, to ensure the delivery speed!

4.Standard 100000 dust-free workshop, strict quality control, more reliable quality, products are exported to all over the world!

5.Customer-centric, to provide the best quality service, free sampling, satisfaction and order again! |