For more custom product options, Contact us!

|

|

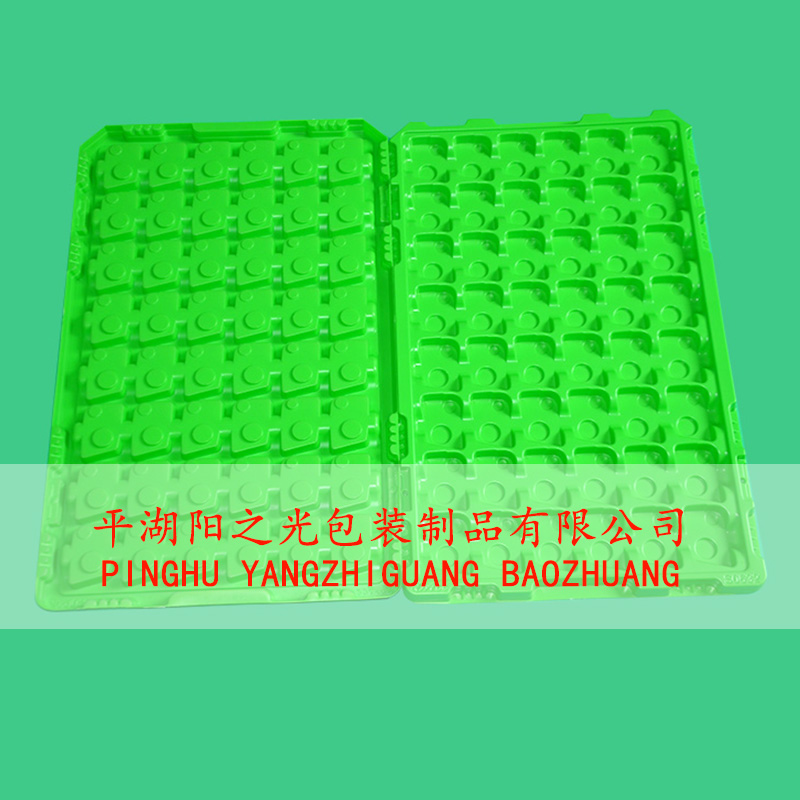

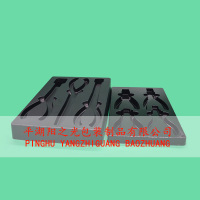

in-plant electronic components transport trays vacuum forming plastic tray esd

Collect

Blister packaging is a popular choice for electronic products due to its attractive appearance and cost-effectiveness. This type of packaging is commonly used for items such as circuit boards, chips, USB drives, headsets, mice, and mobile phones, as well as semi-manufactured electronic components like SD cards and USB interfaces. Electronic blister packaging can be divided into two categories: electronic blister casing and electronic blister tray. Electronic blister casing is created using the blister process, which involves forming a transparent plastic sheet into a specific convex shape that covers the surface of the product. This type of packaging is used to maintain and enhance the appearance of digital electronic products. On the other hand, electronic blister trays, also known as blister inner trays, are made by forming plastic sheets into specific grooves that hold the product securely. These trays are often used for packaging electronic components during transportation and storage. To prevent damage caused by static electricity, anti-static trays are also available.

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686 Why Choose Us? 1. With over 20 years of experience in the plastic industry, we have the expertise to design, develop, and produce all elements of your project in-house. From design to forming and CNC cutting, we can handle complex assembly of the final product for you, ensuring a high-quality end result. 2. As a source factory, we provide product OEM&ODM customization services to meet our customers' specific needs. We work closely with our clients to understand their requirements and provide tailored solutions that exceed their expectations. 3. Our advanced production equipment and efficient supply chain management allow us to deliver products quickly and on-time. With 15 sets of international automatic production equipment and more than 100 employees, we can ensure fast turnaround times without sacrificing quality. 4. Our standard 100000 dust-free workshop and strict quality control measures ensure that our products meet the highest standards of quality and reliability. Our products are exported to customers all over the world, and we take great pride in our reputation for excellence. 5. At our company, we always put the customer first. We provide the best quality service, free sampling, and strive to ensure our customers are completely satisfied with their orders. Our commitment to customer satisfaction has earned us many repeat customers over the years. |