For more custom product options, Contact us!

|

|

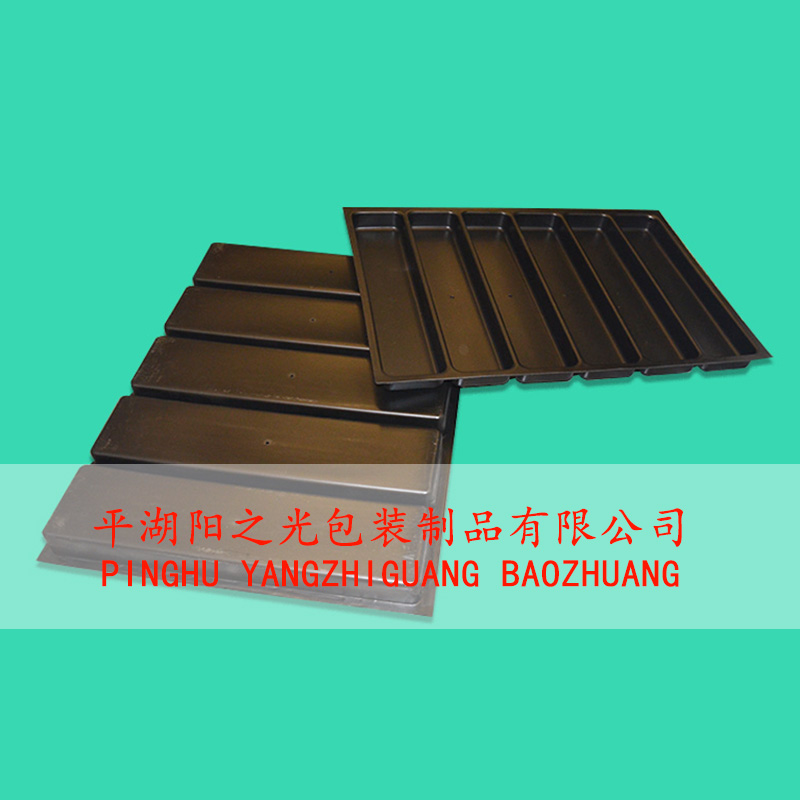

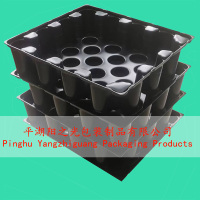

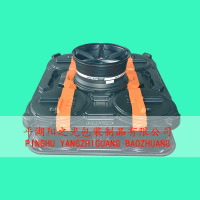

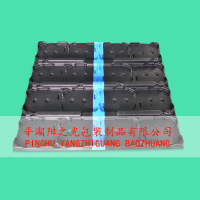

Custom large thick-gauge plastic shipping tray by vacuum forming

Collect

The company's existing design and development staff of 10 people, more than 100 employees. The company can make size thick sheet blister (thickness 1~20mm, specification 2000*1500*700mm). It is widely used in auto parts turnover (composed of nine-foot tray + partition + cover plate), casting turnover, hardware accessories turnover, logistics turnover and other industries.

Pinghu Yangzhiguang Packaging Products Co.,Ltd. founded in 2003, is a leading manufacturer of vacuum forming/thermoforming products. we are able to produce blister packaging, plastic trays, for a variety of industries. any shapes by vacuum forming. Please contact us if you are interested in. thermoforming product is widely used in packaging products such as electronics, automotive parts, medical devices, food, and consumer goods. Thermoforming industrial packaging offers various benefits such as cost-effectiveness, durability, and customization options. Contact Yvonne Liu: +8618821226686, email: wm@shzhanyang.net

Material Options for thick gauge: HDPE, ABS, ABS+TPU, HIPS, PET, PC, PP Material Options for thin gauge: PET, PS, PP, PETG, PVC, ABS, PE, PC, EVA Vacuum forming shipping trays offer several advantages over other types of packaging: 1. Customizable design: Vacuum forming shipping trays can be designed to fit the exact shape and size of the products they are holding, providing a secure fit that reduces the risk of damage during transport. 2. Lightweight: Vacuum forming shipping trays are made from lightweight materials, such as plastic, which makes them easy to handle and transport. 3. Durable: Vacuum forming shipping trays are made from durable materials, such as high-impact polystyrene (HIPS) or polyethylene terephthalate glycol (PETG), which can withstand the rigors of transportation and handling. 4. Cost-effective: Vacuum forming is a relatively low-cost manufacturing process, which makes it an attractive option for companies looking to reduce their packaging costs. 5. Environmentally friendly: Vacuum forming shipping trays can be made from recycled materials, making them a more sustainable option than other types of packaging. The materials used in vacuum forming shipping trays depend on the specific application and requirements of the product being shipped. Some common materials include HIPS, PETG, and polypropylene (PP). These materials offer excellent impact resistance, durability, and clarity, making them ideal for protecting products during transport. Overall, vacuum forming shipping trays offer a cost-effective and customizable packaging solution that can help protect products during transport while also reducing environmental impact.

|