For more custom product options, Contact us!

|

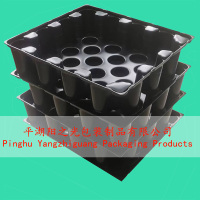

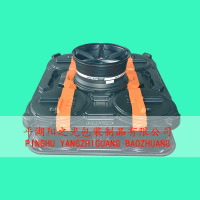

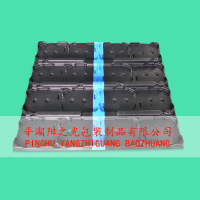

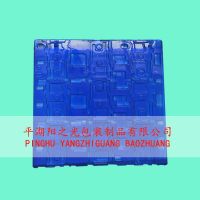

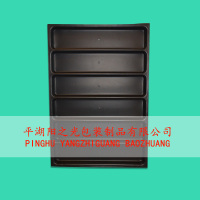

Custom medical machinery thermoformed parts

Collect

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686 Custom thermoformed parts are an important component of many industries, providing a cost-effective and versatile solution for manufacturing a wide range of products. Thermoforming is a process that involves heating plastic sheets until they become pliable and then shaping them over a mold to create the desired shape. These parts can be made from a variety of materials, including ABS, PVC, and PETG, and are used in numerous applications across multiple industries. One of the primary advantages of custom thermoformed parts is their ability to be produced quickly and at a low cost. This makes them an ideal choice for businesses looking to reduce their manufacturing costs without sacrificing quality. Additionally, thermoforming allows for a high degree of customization, with parts available in a wide range of sizes, shapes, and colors to meet specific customer needs. Custom thermoformed parts are used in a variety of industries, including automotive, medical, consumer goods, and industrial applications. In the automotive industry, thermoformed parts are used to create interior trim components, exterior body panels, and other automotive parts. In the medical industry, thermoformed parts are used to create medical devices and equipment housings. In the consumer goods industry, thermoformed parts are used to create packaging, point-of-purchase displays, and other products. In the industrial sector, thermoformed parts are used to create protective covers, enclosures, and other components. Overall, custom thermoformed parts are a versatile and cost-effective solution for a wide range of manufacturing needs. With their ability to be customized to meet specific requirements and their low production costs, they are an ideal choice for businesses looking to improve their bottom line while maintaining high-quality standards. Materials: HDPE, ABS, HIPS, PET, PC, PP and other composite materials; Advantages: stackable, saving space and transportation cost;

Products can be recycled, the service life of up to 5 years, the weight of storage products than their own weight 100 times; Wear-resistant, acid-resistant, alkali-resistant, pressure-resistant shock absorption, environmental protection materials; Custom vacuum forming parts are widely used Why Choose Us? 1. With over 20 years of experience in the plastic industry, we have the expertise to design, develop, and produce all elements of your project in-house. From design to forming and CNC cutting, we can handle complex assembly of the final product for you, ensuring a high-quality end result. 2. As a source factory, we provide product OEM&ODM customization services to meet our customers' specific needs. We work closely with our clients to understand their requirements and provide tailored solutions that exceed their expectations. 3. Our advanced production equipment and efficient supply chain management allow us to deliver products quickly and on-time. With 15 sets of international automatic production equipment and more than 100 employees, we can ensure fast turnaround times without sacrificing quality. 4. Our standard 100000 dust-free workshop and strict quality control measures ensure that our products meet the highest standards of quality and reliability. Our products are exported to customers all over the world, and we take great pride in our reputation for excellence. 5. At our company, we always put the customer first. We provide the best quality service, free sampling, and strive to ensure our customers are completely satisfied with their orders. Our commitment to customer satisfaction has earned us many repeat customers over the years. |