For more custom product options, Contact us!

|

|

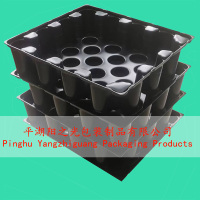

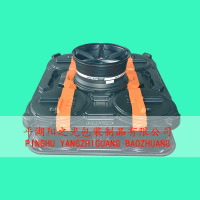

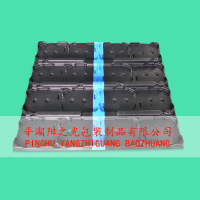

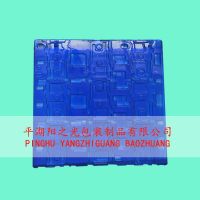

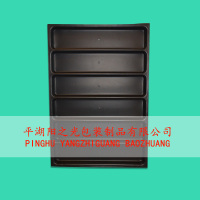

Rigid vacuum forming plastic tray for auto parts-gearbox cover

Collect

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686 Auto parts thermoforming trays, like gearbox covers, protect automotive components during transportation and storage. These custom-designed trays are made from durable and lightweight materials using the thermoforming process. They offer a cost-effective and environmentally friendly solution that can be customized to fit specific dimensions and shapes. Overall, auto parts thermoforming trays are an essential component of the supply chain for many manufacturers and suppliers, ensuring that automotive components arrive at their destination safely and in perfect condition.

Materials: HDPE, ABS, HIPS, PET, PC, PP and other composite materials; Advantages: stackable, saving space and transportation cost; It can be recycled and used for 5 years. The weight of the storage product is 100 times larger than its own weight. Wear-resistant, acid-resistant, alkali-resistant, pressure-resistant shock absorption, environmental protection materials;

Thick sheet blister trays are ideal for use in the automotive industry, casting, hardware accessories, logistics, and other industries. These trays are composed of a nine-foot tray, partition, and cover plate, providing maximum protection during transport and storage. The process of creating thick sheet blister trays involves using 2mm~10mm thickness of the plate or sheet, which is then softened by heat and molded using vacuum negative pressure to create the desired shape. The excess material is removed using a plate cutter, die cutter, stamping, or trimming machine, resulting in the final desired shape. One of the primary advantages of thick sheet blister trays is their low mold cost, short production period, and reduced mold development time. This makes them a cost-effective solution for businesses looking to reduce their manufacturing costs without compromising on quality. Additionally, these trays can be customized to meet specific customer requirements, ensuring precise product assembly and maximum protection during transport and handling. Overall, thick sheet blister trays are an essential component of the supply chain for many manufacturers and suppliers. With their ability to provide maximum protection during transport and storage, they ensure that products arrive at their destination safely and in perfect condition. |