For more custom product options, Contact us!

|

|

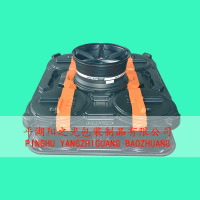

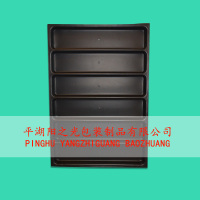

Custom Vacuum Forming Tray for Car Flywheel - Pinghu Yangzhiguang Packaging Products

Collect

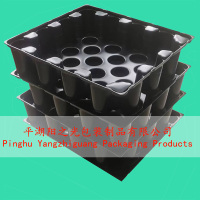

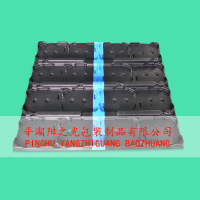

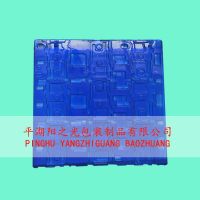

A custom vacuum forming tray for a car flywheel is a specially designed tray made through the vacuum forming process to securely hold and protect the car flywheel during storage, transportation, or assembly processes. The tray is typically made from a durable and rigid plastic material that can withstand the weight and shape of the flywheel, ensuring its safe handling and preventing any damage. The specific design and dimensions of the tray will depend on the size and shape of the car flywheel it is intended to hold. The tray will be customized to fit the contours and dimensions of the flywheel precisely, providing a snug and secure fit. It may also include additional features such as cutouts or recesses to accommodate other components or accessories related to the flywheel. The vacuum forming process involves heating a sheet of plastic until it becomes pliable, then placing it over a mold of the desired shape, and applying vacuum pressure to force the plastic to conform to the mold's contours. Once cooled and solidified, the plastic retains the shape of the mold, creating the custom tray. The benefits of using a custom vacuum forming tray for a car flywheel include: 1. Protection: The tray provides a protective barrier around the flywheel, preventing scratches, dents, or other damage that could occur during handling or transportation. 2. Organization: The tray helps keep the flywheel organized and secure, reducing the risk of misplacement or loss. 3. Efficiency: Using a custom tray allows for easier handling and assembly of the flywheel, saving time and effort during production or maintenance processes. 4. Customization: The tray can be tailored to meet specific requirements, such as incorporating branding, labeling, or additional compartments for related parts or tools. Overall, a custom vacuum forming tray for a car flywheel offers a practical and efficient solution for safe storage, transport, and assembly of automotive components.

The company has a dedicated team of 10 design and development professionals, along with over 100 skilled employees. With our expertise, we are capable of producing thick sheet blisters in various sizes (ranging from 1 to 20mm in thickness and 2000*1500*700mm in dimensions). These blisters find extensive applications in industries such as auto parts transport (consisting of a nine-foot tray, partition, and cover plate), casting transport, hardware accessories transport, as well as logistics transport. Trust us to provide reliable solutions tailored to your specific industry needs. Thick sheet blister offers a range of advantageous features including space-saving design, pollution-free composition, compact size, durability, and recyclability. The material options for thick sheet blister include HDPE, ABS, HIPS, PET, PC, PP, and other composite materials. On the other hand, thin sheet blister (ranging from 0.2 to 2mm in thickness) finds extensive use in industries such as food, medicine, daily necessities, cosmetics, hardware electronics, toys, stationery, and agricultural production. The key features of thin sheet blister include affordability, user-friendliness, recyclability, and environmental friendliness. It is manufactured using PVC, PET, HIPS, PP, PETG, ABS, PE, EVA, gold-plated, flocking materials of various colors. Choose thick or thin sheet blister based on your specific requirements and enjoy the benefits of their respective features. Trust us to provide high-quality solutions that cater to your industry needs.

This process has the advantages of low mold cost, short production period and short mold development time. Greatly reduce the product cost and development cycle. According to customer requirements to produce a variety of specifications and sizes of products, enough to ensure your product assembly accuracy. |